Alnico Magnets

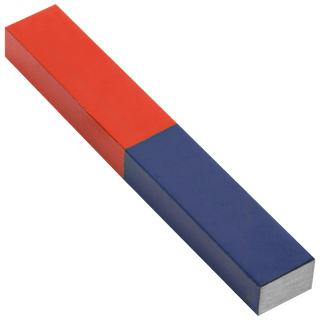

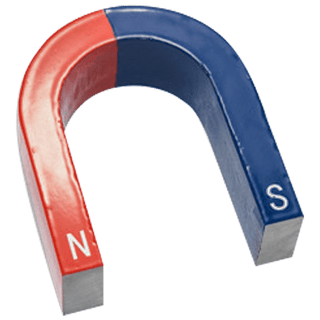

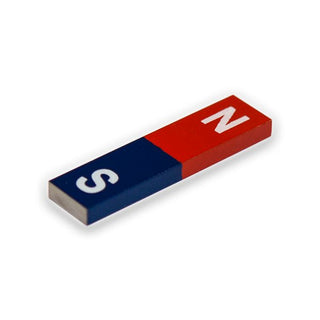

Alnico is the acronym for the alloy that creates this magnet: aluminium (Al), nickel (Ni) and cobalt (Co). Our Alnico magnets also contains iron and are produced by casting or powder metallurgical techniques. Choose Alnico Magnets for greater mechanical strength, high temperatures and corrosion resistance. Although Alnico might be the weakest of permanent magnets, it presents a greater mechanical strength than Neodymium of Ferrite magnets and has an excellent temperature coefficient that gives it exceptional stability, even during extreme temperature fluctuations and makes it able to tolerate high temperatures up to 500°C. Another of its properties is its high resistance to corrosion. Very hard but brittle, our economical Alnico magnets produce an important flux density. However, they are not suitable for high-friction or repelling applications and present a low resistance to demagnetisation. Alnico magnets are utilised in the mechanical, electrical automotive, aviation, medical industry and in military technology. They are also commonly used for educational purposes due to their painted pole colours for pole identification. More famously, they are a top grade material for electric guitar pickups: Fender has been using Alnico Rod Magnets to build their electric guitar middle-tone, neck and bridge pickups since the late 1940s. Check our Alnico Magnets in various shapes and sizes: Cylinders, Shallow Pots, Blocks or our Alnico Horseshoe Magnets.

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Alnico Horseshoe Magnet - 75mm x 38mm x 9mm

Code: 49011

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Alnico Cow Magnet - 75mm x 12mm | Rod Magnet

Code: 49025

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Alnico Rod Magnet - 5mm x 20mm

Code: 44030

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Alnico Horseshoe Magnet - 51mm x 41mm x 16mm

Code: 49015

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Alnico Block Magnet - 40mm x 12mm x 5mm

Code: 45020

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1

Alnico Rod Magnet - 4mm x 20mm

Code: 44010

Not enough in stock. Please choose a lower quantity.

Minimum order quantity is 1