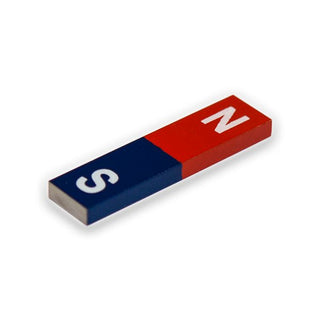

Alnico Block Magnets

Alnico Block Magnets, also called Bar magnets, have a high residual induction, an exceptional temperature stability over an extensive range of temperatures and a great resistance to corrosion. They are both hard and brittle. Although these magnets are characterised as the weakest of permanent magnets, they are the best choice for numerous manufacturing applications owing to their mechanical strength, which is greater than either Neodymium or Ferrite magnets. Magnetic Alnico Blocks or Bars are generally used for Education purposes, from primary school to postgraduate work. They are a perfect tool for science projects and demonstrations and experimental applications thanks to their North and South poles indications. These particular magnets play a decisive role in many everyday devices that people love because they make our life easier. Indeed, you can find Alnico Blocks or Bars in small direct current motors (DC motors) used to power a whole host of toys but also day-to-day tools and appliances such as refrigerators, washing machines, telephones, pumps, filters or security systems. These versatile magnets are also included in the manufacture of larger DC motors. The latter converts electrical current (or direct current) into a mechanical power (force and movement) through the action of magnetic fields, thereby producing a propulsive energy to shift electrical vehicles, elevators, hoists and generators. Alnico Block Magnets are employed in various measuring sensors; you can find them in temperature and pressure sensors and gauges used for cool rooms in food delivering and distribution. Last but not the least. Magnetic Blocks and Bars made of Alnico are fundamental in modifying, amplifying and clarifying audio signals for a high fidelity sound; that is why they are largely used in the the audio and music industry for loudspeakers, microphones or guitar pickups.

8 items

Best Sellers

Alnico Block Magnet - 40mm x 12mm x 5mm

Code: 45020

Alnico Pot Magnet - 27mm x 25mm

Code: 47130

Alnico Pot Magnet - 17.5mm x 16mm

Code: 47110

Alnico Block Magnet - 75mm x 15mm x 10mm

Code: 45060

Alnico Block Magnet - 50mm x 15mm x 10mm

Code: 45030